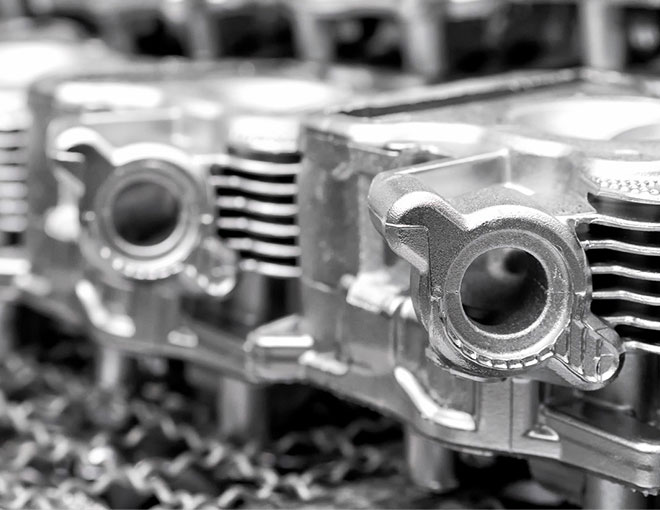

Testing the finished die cast product is an essential step in the manufacturing process that cannot in any way, shape, or form be skipped under any circumstances. The finished product must first be put through its paces in terms of quality assurance before moving on to the next stage. It is possible for a die cast to fail in any one of a large number of different ways; the results for your finished products could be disastrous if any of these flaws are overlooked. There are a large number of different ways that a die cast can fail. Die castings have the potential to fail due to any one of these many different reasons. It is absolutely necessary to have an effective quality control procedure in place in order to be able to test for each and every one of the potential failure scenarios. This can be determined by subjecting the component that was die cast to a battery of tests in a range of different environments. Porosity

Porosity is the condition that happens when there are air bubbles that become trapped in the part during the process of die casting

This can cause the part to have a porous appearance

These air bubbles can give the part an uneven or porous appearance, depending on how many there are

Either an excessive number of relatively insignificant voids or a few significantly larger voids can significantly undermine the structural integrity of the finished part

However, an excessive number of relatively insignificant voids is more likely to have this effect. Either an excessive number of relatively insignificant voids or a few significantly larger voids can significantly undermine the structural integrity of the finished part. However, an excessive number of relatively insignificant voids is more likely to have this effect.

When conducting tests to determine whether or not a material is porous, quality assurance professionals will most commonly use either X-ray analysis or destructive testing as the two methods. Both of these testing methods can be destructive. Casting techniques that are done correctly should prevent catastrophic porosity, but even if they do, it is imperative that every effort be made to avoid it. Casting techniques that are done incorrectly should not prevent catastrophic porosity. It is of the utmost importance to make every effort possible to avoid excessive porosity when die casting, and one of the ways that this can be accomplished is by making use of good process controls. When die casting, it is of the utmost importance to make every effort possible to avoid excessive porosity.

2. A dishonest representation of one's self made publically available to other people.

Due to the significance of this aspect of the casting, it is of the utmost importance to establish visual criteria for the surface appearance of the casting. This is one of the most important steps in the custom die casting process. During this time period, the product is still in the stage of the conceptualization process. The need for retooling or insufficient quality control during the aluminum die castings process is almost always the most obvious cause. After that, it is the responsibility of the die caster to produce a written cosmetic standard that will act as a resource for the quality team as they manufacture the product. This is the only method that can be used to determine whether or not a component actually appears in the correct manner as it should.

3. Dimensional Problems

If the die becomes worn over time or if there is movement between the two halves of the die, it is possible that some of the parts will not conform to the expected dimensions. This can happen if there is movement between the two halves of the die. Both of these outcomes are entirely conceivable. Due to the fact that the die is split into two halves, there is the possibility that this outcome will occur. Even though it's possible that these dimensional problems are too subtle to be seen with the naked eye, this does not mean that they will not cause problems in the long run. The only way to tell for sure is to wait and see. In point of fact, all that it means is that we won't be alerted to their presence right away. The die caster will be able to demonstrate their capability to meet the dimensional tolerances that have been specified as a result of this. During the zinc alloy die casting process, it is the responsibility of the quality control team to ensure that they do not, under any circumstances, forget to take measurements of any critical dimensions. It is possible that the measurements will be very easy to understand, but there is also the possibility that they will require the utilization of more complex apparatus.

If you notice that there are consistent problems with the dimensions of the product or that there is a lack of repeatability, you should probably consider retooling or repairing the mold. Other possible solutions include replacing the mold altogether. You also have the option of completely altering the mold by switching it out for something else. The instructions pertaining to the application of paint and the assembly of the product have been omitted. procedures that were left out are included.

When it comes to issues with the workpiece's overall appearance, the only real way to tell if you have forgotten something in the process of finishing or assembly is to look at the workpiece itself. This is because looking at the workpiece is the only way to really tell if you have forgotten something. Taking a look at the finished product is the only way to determine whether or not you missed something. When problems of this kind arise, it is almost always the case that the procedure was carried out in an incorrect manner, which is the reason why the problem occurred. This is the reason why the problem occurred.

This is because glancing at the finished product is the only way to definitively determine whether or not you have overlooked any steps in the process. When problems of this nature arise, it is important to keep in mind that the only way to truly tell if you have forgotten anything is to look at the workpiece. This is the only way to determine if you have overlooked anything. They are able to do this because they have an innate comprehension of the significance of maintaining quality control, which allows them to accomplish this task.

Porosity is another prevalent factor that contributes to the problem. Additionally, the component in question may be subjected to a predetermined amount of pressure while simultaneously being submerged in water for a predetermined amount of time. This may be done while simultaneously being subjected to a predetermined amount of time. In the event that this process is carried out, the component might end up having a higher porosity than it did before. To put it another way, they will be in a position to provide a quality assurance for the goods that they manufacture.

6. Determining whether or not there is an issue with the trimming shouldn't present too much of a challenge for you; however, you can use these methods to test for issues with the trimming that are more severe. All three of these facets of the scenario have the potential to be factors that contribute to the problem. These three aspects of the situation each contribute in their own way to making the problem even more severe, which is further compounded by the fact that all three of them are interconnected. All three of these facets of the scenario have the potential to be factors that contribute to the problem. All three of these facets of the scenario have the potential to be factors that contribute to the problem. In the vast majority of cases, determining whether or not there is a problem with the trimming should not present too much of a challenge. These three aspects of the situation are in the vast majority of cases, determining whether or not there is a problem with the trimming should not present too much of a challenge.