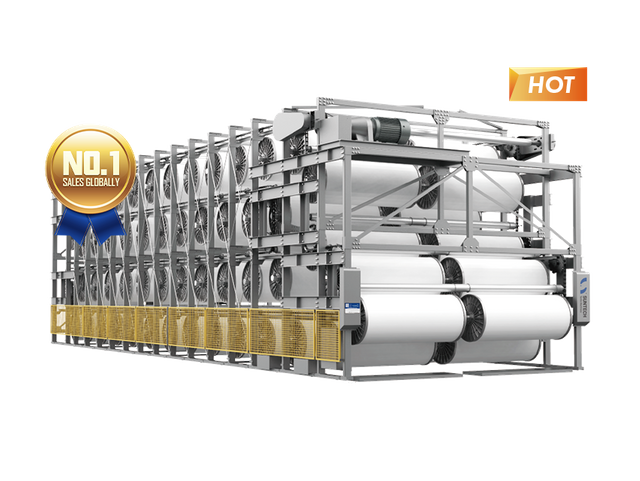

In the ever-evolving landscape of manufacturing, the beam storage factory has emerged as a pivotal component in optimizing space and enhancing operational efficiency. This article delves into the numerous advantages of implementing beam storage systems, providing insights that are essential for manufacturers aiming to stay competitive.

Understanding Beam Storage Systems

A beam storage factory utilizes a series of horizontal beams to create a robust framework for storing materials and products. These systems are designed to maximize vertical space, allowing for higher storage density without compromising accessibility. But what makes these systems particularly advantageous in modern manufacturing?

1. Enhanced Space Utilization

One of the primary benefits of a beam storage factory is its ability to optimize space. By utilizing vertical storage, manufacturers can significantly reduce their floor space requirements. This is especially beneficial for facilities with limited square footage. Consider the following:

- Increased storage capacity without expanding the facility.

- Efficient organization of materials, reducing clutter.

- Improved workflow and accessibility to stored items.

2. Improved Inventory Management

Effective inventory management is crucial for any manufacturing operation. Beam storage systems facilitate better tracking and organization of materials. With clearly defined storage locations, manufacturers can quickly locate items, leading to reduced downtime. How does this impact productivity?

- Faster retrieval times for materials.

- Minimized risk of stock discrepancies.

- Enhanced ability to conduct regular inventory audits.

3. Flexibility and Scalability

Another significant advantage of a beam storage factory is its inherent flexibility. These systems can be easily adjusted or expanded to accommodate changing inventory needs. This adaptability is vital for manufacturers facing fluctuating demand. What are the implications of this flexibility?

- Ability to scale operations without major renovations.

- Customizable configurations to suit specific storage requirements.

- Long-term cost savings through efficient resource management.

4. Safety and Ergonomics

Safety is paramount in any manufacturing environment. Beam storage systems are designed with safety features that minimize the risk of accidents. Additionally, these systems promote ergonomic practices by reducing the need for excessive lifting and reaching. How can manufacturers ensure a safe working environment?

- Implement regular safety training for employees.

- Utilize equipment that supports ergonomic handling of materials.

- Regularly inspect storage systems for maintenance needs.

Conclusion

In conclusion, the advantages of a beam storage factory are manifold, ranging from enhanced space utilization to improved safety. As manufacturers strive for efficiency and productivity, investing in beam storage systems can yield significant returns. For those interested in exploring these systems further, consider visiting  for more information on beam stackers and their applications in modern manufacturing.

for more information on beam stackers and their applications in modern manufacturing.